Reverse Logistics in 2025: What, When & How

- What Is Reverse Logistics?

- When Is Reverse Logistics Used?

- How Does Reverse Logistics Create Value?

- Categories of Reverse Logistics

- 5 R’s of Reverse Logistics

- Advantages of Effective Reverse Logistics

- Types of Reverse Logistics

- Reverse Logistics Process

- Challenges in Reverse Logistics

- Reverse Logistics vs. Reverse Supply Chain?

- Reverse Logistics Companies in India

- How to Choose the Right Reverse Logistics Company

- 7 Strategic Approach to Improve Reverse Logistics

- Conclusion

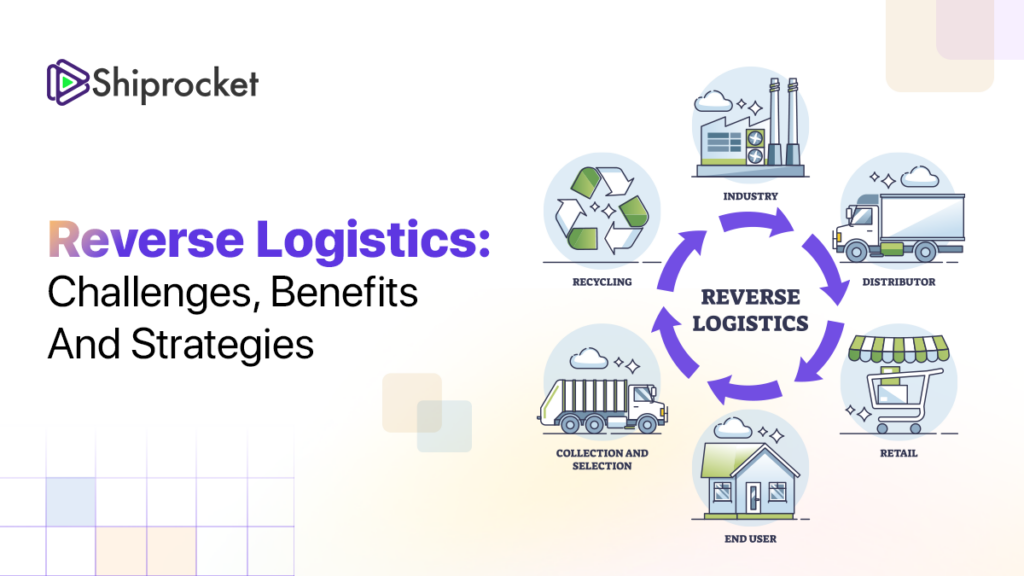

eCommerce businesses require managing the flow of goods efficiently not only from manufacturers to consumers but also in the reverse direction. This process is referred to as reverse logistics. While logistics focuses on delivering products to customers, reverse logistics mainly includes product returns.

As per India Reverse Logistics Market Report 2022-2027, the reverse logistics market in India is likely to reach USD 39.81 Bn by the year 2027. The process has its set of benefits and challenges.

In this article, we’ll discuss all about reverse logistics. This includes the strategies employed to streamline the process, the benefits it can yield, and the challenges it involves.

What Is Reverse Logistics?

Reverse logistics mainly involves moving finished goods/ raw materials from the customers back to the manufacturer or supplier. The return, recycling, remanufacturing, and disposal of products and materials after reaching the end consumer are all covered under this process.

This practice is important for reducing waste. It is an effective way to minimise environmental impact and recover value from returned or discarded products. With the help of reverse logistics, companies optimise their supply chains and improve sustainability.

When Is Reverse Logistics Used?

Reverse logistics is mainly used in the post-consumer phase of a product’s lifecycle. It plays a significant role in managing returned goods. It makes sure the product return process runs seamlessly. It is also used during the recycling and remanufacturing of products while managing excessive inventory and for the recovery of packaging materials.

How Does Reverse Logistics Create Value?

Here is how reverse logistics creates value:

- It promotes sustainable business practices by reducing waste and lowering harmful impacts on the environment.

- It helps derive value from returned items.

- It improves customer satisfaction by managing product returns and warranty repairs seamlessly.

Categories of Reverse Logistics

- Product Returns: Businesses use reverse logistics to manage returned goods.

- Remanufacturing and Refurbishing: It also involves disassembling and rebuilding products to add value to them.

- Warranty and Repairs: Service providers use reverse logistics to handle warranty claims and repairs wherein the items need to be picked from the customers.

- Excess Inventory Management: Retailers manage excess or unsold inventory by returning it to suppliers or redistributing it using a reverse logistics process.

- Delivery Failure: In many cases, the driver fails to deliver the product to the consumer because of various reasons. In such a case, he brings the products back to the sorting centers. From there, the products are returned to their original point.

- Recycling and Waste Management: It is also used by organisations during the process of recycling and disposal of products or materials. Waste products are disposed of in an environmentally responsible manner using this process.

- Rentals: When the rental contract of a product or equipment ends, it is returned to its owner with the help of reverse logistics.

- Reusable Packaging: Businesses also use reverse logistics to recover and reuse packaging materials such as containers and crates.

5 R’s of Reverse Logistics

The 5 R’s of Reverse Logistics are as follows:

- Return: The first R is all about managing the returned products. It ensures that the items returned by the consumers are assessed properly and shipped back to the supplier or manufacturer.

- Reselling: Reselling the returned goods to new customers also comes under this process. The returned goods that are unused and in good condition are tagged back into the system for the purpose of reselling.

- Repair: The process also comes into play when a customer wants an item to be repaired. The product is inspected, picked from the customer, and sent for repair.

- Repackage: The returned goods are sent for repackaging using reverse logistics. This helps in optimising the condition of these goods and prepares them for resale.

- Recycle: It promotes the recycling of used products and materials. This helps in lowering landfill waste and building a cleaner and sustainable environment.

Advantages of Effective Reverse Logistics

Let’s take a look at the various advantages of effective reverse logistics:

1. Enhances Customer Satisfaction: This process helps streamline the procedure of return of goods. It also helps in managing the warranty and repair processes effectively. This, in turn, enhances overall customer satisfaction.

2. Promotes Sustainability: It reduces waste in the environment, thereby promoting cleanliness and sustainability.

3. Boosts Credibility: It demonstrates a business’s commitment to environmental responsibility, adding to its credibility.

4. Increases Profitability: Recycling the products and materials helps the companies optimise resource utilisation and recover value.

5. Reduces Risk Management: It helps protect businesses from risks related to the exchange and disposal of products. Some products need to be disposed of immediately because of safety recalls. Reverse logistics addresses this requirement timely.

Types of Reverse Logistics

Listed below are the primary types of reverse logistics:

Returns Management

Returns management is a fundamental aspect of reverse logistics that focuses on handling customer returns of goods. It includes managing the entire return process, from receiving returned items to inspecting them for quality and determining the appropriate course of action. Companies often implement efficient returns management systems to streamline the return process, enhance customer satisfaction, and minimise losses. For example, an online retailer may have a dedicated returns portal where customers can initiate the return process and receive instructions on returning the product.

Return Policy and Procedure (RPP)

Return policy and procedure (RPP) refers to the guidelines and protocols established by businesses to govern the return process. It outlines the conditions under which customers can return products, the timeframe within which returns are accepted, and the steps involved in initiating a return. A clear and well-defined RPP helps manage customer expectations and ensures consistency in handling returns. For instance, a company may have a 30-day return window and require customers to provide proof of purchase for all returns.

Remanufacturing or Refurbishment

Remanufacturing or refurbishment in reverse logistics refers to the process of taking used goods and restoring them so they can be sold or used again. This involves repairing, cleaning, and fixing up the products to make them usable and reduce waste. When companies remanufacture products, they might use a combination of reused, repaired, and new parts. For instance, if a computer manufacturer receives returned laptops, they can refurbish them by replacing any broken parts and making sure they meet the required quality standards before selling them again at a lower price.

Reverse Logistics Process

Reverse Logistics process refers to the management and return of the products from customers back to the merchant through the supply chain. The most common example of reverse logistics is when a customer returns the purchased product and asks for a refund.

The whole process varies from industry to industry and is entirely different from traditional logistics. As mentioned above, reverse logistics involves everything from the return initiation to the entire product management at the merchant’s warehouse. The different steps in the process consist of packaging, shipping, customer support, restocking or disposing of the product through various means.

The process of reverse logistics is as follows:

- The customer decides to return the purchased item.

- Once the customer requests the return, the shipment is taken back to the merchant’s warehouse. This is the step where the merchant needs to place the return in the appropriate category before it arrives. For example, we often see various eCommerce giants, such as Amazon, Flipkart etc., asking their customers to fill out the reason for their return, be it a defective item, wrong product received, or product damage issues.

- The incoming returns go through a complete review process where sellers place the sellable items back on the shelf. Faulty or defective items must be repaired quickly to get restated in the main inventory.

- The customer gets a full refund if the quality of the order qualifies for it.

However, Businesses must follow a strategic approach to ensure maximum efficiency and implement a robust reverse logistics process.

Challenges in Reverse Logistics

Some of the common reverse logistics challenges are as follows:

- Space Constraints: Businesses often face space constraints when it comes to storing goods that are returned. Statistics reveal that reverse logistics need an average of up to 20% additional space than forward logistics.

- Expensive: It involves a lot of expenses, such as transportation costs, processing expenses, and the cost of inspecting.

- Complicated Returns: Reverse logistics can be a complicated process as it involves a number of steps. This includes inspecting the goods, processing them, repairing, recycling, repackaging, and more.

- Overhead Costs: Reverse logistics means extensive costs for your business. You not only have to pay for forwarding orders but also for the return orders that the courier company will arrange for you. Since free returns are quite the trend these days, you must handle these costs yourself.

- Product Quality: Undoubtedly, it takes a lot to maintain the quality of the product. The product would now be more prone to bumps and friction as the packaging would be opened and will not be the same. Also, sometimes customers return used items, and you cannot use the product again. Therefore, it’s important to ensure you add the conditions for returning the products and don’t return everything. You can also collect photographs to assess the condition of the product.

- Negative Customer Experience: Lastly, reverse logistics can negatively impact customer experience if not done correctly. Therefore align your return pickups properly and take proper customer feedback to know when they can return the product.

Reverse Logistics vs. Reverse Supply Chain?

| Points of Distinction | Reverse Logistics | Reverse Supply Chain |

|---|---|---|

| Definition | Involves the movement of goods from consumers to the manufacturer or supplier. | Involves the movement of goods from consumers to the manufacturer or supplier. |

| Focus | Mainly deals with managing the return of goods with a focus on product recalls and recycling. | Focuses on the process of remanufacturing, refurbishing, and repackaging of goods |

Reverse Logistics Companies in India

Various Indian companies offer reverse logistics solutions to meet the growing demand for efficient return management, especially in eCommerce and retail sectors.

Blue Dart

Blue Dart Express Ltd., based in Mumbai, is a leader in logistics services across India. Since its establishment in 1983, the company has grown to cover over 35,000 locations in the country. With a vast distribution network and advanced technology, Blue Dart ensures secure delivery.

It provides a wide range of services, including customs clearance, supply chain solutions, and freight forwarding. Blue Dart also runs warehouses in major metro cities and offers time-sensitive delivery via its Blue Dart Aviation subsidiary.

Ecom Express

Ecom Express is an end-to-end logistics provider headquartered in Gurugram, Haryana. Founded in 2012, the company has made its mark in the Indian eCommerce industry by offering customised, scalable, and sustainable solutions. Ecom Express provides a variety of services like first-mile pickup, network optimisation, and last-mile delivery.

With a presence across 29 states and more than 27,000 PIN codes, the company serves a wide geographic area, including major towns and cities. It has also expanded to Bangladesh by investing in Paperfly, the largest third-party eCommerce logistics company in the region.

Xpressbees

Xpressbees, founded in 2015 in Pune, Maharashtra, offers specialised reverse logistics services. The company provides solutions like Last-Mile Delivery, dropshipping, channel management, and payment collection.

With a presence in over 2000 cities and towns, Xpressbees partners with various industries, including eCommerce, healthcare, and automotive. It has more than 3000 service centers, 52 cargo airports, and 100 fulfillment hubs under its wing. The warehouse currently has a capacity of over 1 million square feet.

Shadowfax

Shadowfax, founded in 2015, is a logistics company reputed for its engagement of advanced technology such as machine learning and artificial intelligence to ease the hyperlocal distribution process and provide timely and effective deliveries. Currently serving over 600 cities in India, the company is committed to fulfilling up to 1 million orders a day.

Launched in 2021, Shadowfax’s delivery platform provides its delivery partners with multiple opportunities for their growth. With a strong team of over 5000, Shadowfax is working its way to enhance its share in reverse logistics.

Delhivery

Delhivery, the leading company in the Indian logistics market, has completed 1 billion-plus shipments since its inception. The company is known for its end-to-end fulfillment solutions for 17,000-plus pin codes across 175 cities in India.

Delhivery offers some of the most comprehensive logistics delivery features, including real-time shipment tracking by SMS and multiple payment options. With a focus on high-quality logistics operations, the company is helping shape the future of reverse logistics in India.

How to Choose the Right Reverse Logistics Company

Choosing the right reverse logistics company is vital for businesses dealing with product returns. Here are some factors to consider when selecting the right partner for your reverse logistics needs.

Industry Expertise

Choose a reverse logistics provider with an extensive experience in your line of industry. Such an experienced partner will already have knowledge of the complexities in your business that they can solve. Their experiences with your market and how returns are handled for your product will enable them to offer you specific services tailored toward your goals.

Service Offerings

Check that the reverse logistics partner does all that you need them to do; whether it be to facilitate various returns or even offer value-added services, such as repackaging or quality checks. Look at the range of services and whether they can fulfill your needs, be it defective goods processing or excess inventory handling.

Technological Capabilities

A company that uses advanced technology can make a big difference in managing returns. Look for a provider that offers tools for tracking returns, data analysis, and seamless integration with your existing systems. This helps simplify processes, reduce errors, and improve efficiency.

Network Reach

The company’s network coverage is important, especially if you serve customers in various locations. Choose a reverse logistics partner with a broad reach and the capacity to handle returns from different regions. This ensures that returns are processed swiftly, no matter where your customers are located.

Cost and Value

While cost is a huge factor, one has to measure the value the reverse logistics provider brings to your business. It could include transparent pricing and rates competitive enough as compared to the rest of the market for the quality of services provided. A good partner will help cut down on reverse logistics costs while enhancing efficiencies and eventually driving revenue.

Communication and Collaboration

Communication is one of the factors that ensures a successful relationship. The reverse logistics company, therefore, needs to update regularly regarding the status of returns and should allow the team to be kept in the loop. They should keep an open channel for feedback and closely work with your resourceful team to resolve issues that arise.

Sustainability Practices

If eco-friendly practices are important for your business, choose a reverse logistics partner that shares your commitment to sustainability. Look for companies that focus on responsible disposal, recycling, and other eco-conscious practices. This not only supports environmental goals but can also enhance your brand’s reputation.

7 Strategic Approach to Improve Reverse Logistics

Improving reverse logistics is crucial for enhancing sustainability and managing costs. Here are seven strategic approaches to achieve this:

- Analyse the Data: Collate necessary data to understand which products are being returned more often. This will also give you an insight into why the products are being returned. You may make modifications to your products to lower the rate of return.

- Review and Modify Return Policies: Review your organisation’s return and repair policies and make strategic changes to ease the reverse logistics process.

- Maintain Cordial Relationships with Suppliers: It is important to maintain a cordial work relationship with the suppliers to ensure a seamless experience.

- Centralise the Return Centers: Establishing a central return center assists you in categorizing products and determining their true worth. It also makes it easier for businesses to figure out what to do with returned goods.

- Assess the Transportation Cost: Assess the cost involved in the transportation of goods and try to integrate some of the forward and reverse logistics processes. This will help reduce the overall cost.

- Efficient Return Management System: It is suggested to employ an automated return management system to streamline the process.

- Clear Communication: Educate the customers about your return policy. This can reduce the number of unnecessary returns.

Conclusion

As a business owner, you must master the process of reverse logistics. Among other things, it helps reduce expenses, provides sustainability benefits, and enhances customer satisfaction by creating a better return experience. There are certain challenges involved in the process. However, you can overcome them with the strategic approaches shared above.

The key barriers to reverse logistics can be a lack of expertise in the field, lack of commitment, improper infrastructure, or non-availability of adequate funds.

Yes, data analytics helps in understanding the return patterns, using which you can figure out the scope for process improvement. It helps in making better decisions to optimise reverse logistics.

Reverse logistics mainly helps in managing product returns efficiently. It helps reduce waste and boost sustainability, in addition to deriving value from returned products.