Outbound Logistics: Key Elements and Operational Procedures

- Understanding Outbound Logistics

- The Influence of Outbound Logistics on the Distribution of Finished Goods

- Outbound Logistics Activities

- The Core Elements of Outbound Logistics

- Unveiling the Steps in the Outbound Logistics Process

- Strategies for Optimising Outbound Logistics

- The Advantages of Optimised Outbound Deliveries

- Navigating the Distribution Channels in Outbound Logistics

- Impact of Outbound Logistics on Customer Experience

- Outbound vs. Inbound Logistics: The Contrasting Features

- Conclusion

Refining your logistics operations can help you have an efficient supply chain, which is necessary to meet your customers’ requirements accurately. When considering logistics, you need to think about both inbound and outbound logistics. Enhancing both processes is essential to give customers a more satisfying shopping experience.

You may be dealing with delayed orders, erroneous invoices, shipment errors, poor customer experience, and inadequate inventory supplies. These are easily avoidable mistakes that add to your costs and even lead to loss of customers at times. That’s where the need to understand and strengthen outbound logistics comes in. Nearly 80% of businesses with optimally-performing supply chains witnessed an above-average revenue growth.

This article will illustrate the workings of an effective outbound logistics system in detail for your company’s benefit.

Understanding Outbound Logistics

Outbound logistics is a process that helps you store, transport, and deliver your goods to your end customers and fulfill orders.

A fully optimised outbound logistics system involves many elements and intricacies, as getting orders ready for sale and achieving timely delivery is not child’s play. According to a 2022 report by Convery, 53% of eCommerce retailers find logistics and shipping processes challenging.

Having a streamlined outbound logistics process helps you alleviate the complexities and get a perfect last-mile delivery each time.

However, businesses need to know how outbound logistics impact their operations to master their logistics process.

The Influence of Outbound Logistics on the Distribution of Finished Goods

Outbound logistics operations influence the distribution of products from your production site to your end customer’s location. If you encounter any delays in this process, it can become an unwelcome extra expense for you and your suppliers. You’re also likely to miss your manufacturing deadlines due to unavailable raw materials.

Consequently, the failure to deliver on time can drive your buyers to competitors, impacting customer retention and profitability. A study by Voxware reveals that

17% of consumers may cease buying from an eCommerce retailer post just one late delivery instance, which rises to 55% in case of two to three delayed deliveries. Moreover, if you’re transporting perishable goods, these delays can massively reduce or completely strip them of their value.

You may also face unsuccessful deliveries due to security threats, like theft and hijacking, risking your inventory. These threats can be internal, coming from your employees with an intent to steal or sabotage your inventory, and external threats, like cyber-attacks.

Another factor is poor route planning, which can cause traffic congestion, wasted time, and increased fuel consumption. It leaves you with higher costs and higher risks for your drivers, including potential overtime and additional hiring expenses.

A solid outbound logistics system increases your shipment’s visibility, allowing you to resolve any issues during transit immediately. It also helps you provide satisfactory customer service by keeping your buyers informed through real-time updates.

Outbound Logistics Activities

Businesses must pay close attention to outbound logistics activities since small errors can cost you and your brand’s image heavily.

Accurate order entry that prevents issues like duplicate orders, incorrect quantities, wrong products, and incorrect shipping addresses, using advanced logistics management technology is important. This helps manage these processes in real time and allows customers to update orders before shipping.

Having your shipments delivered on time depends on accessible inventory-on-hand data for employees. It ensures immediate and future order fulfillment by keeping a check on stock availability and replenishing it before a product goes out of stock. A proper outbound logistics system saves manual picking and packing errors that arise from the complexity of this process.

Moreover, replenishment operations, including various picking methods, like label-based, paper-based, line, cluster, and zone picking are also vital for preparing future deliveries. Well-sought outbound logistics activities optimise these operations and reduce manual labour.

Lastly, improper packing can directly impact delivery accuracy. It is a complicated process and includes many steps: packaging, labelling, inspecting, and routing. Slipping up on any of them can delay your shipments and hamper customer relations.

The Core Elements of Outbound Logistics

When moving your goods, it is inevitable to learn about the different components of the outbound logistics process:

Storage/Warehousing

Warehousing is stocking your inventory safely in a storage facility for future sale. This warehouse may belong to you or a third-party logistics company. Having your storage center involves hefty investment and costs while outsourcing one can be far more pocket-friendly for you.

Managing Stock

It matters how you pick, pack, and store your finished products in an appropriate place. You can manage your inventory with precision by integrating it with software systems that help you track it, allowing you to replenish stock as and when needed, forecast future demands, and count inventory.

With this advanced technology, you can eliminate human errors and get your shipments ready quickly when an order pops up on your dashboard.

Transporting Goods

Transportation in outbound logistics lays focus on how you ship your products to your distribution or fulfillment hubs. Businesses usually move goods in freight trucks, planes, or sea vessels.

This stage usually decides whether your delivery is a success or failure. This is because the shipments entail many risks, like delays, theft, damage, or loss in the transit period. So, you must take considerable measures to improve this aspect of your supply chain.

Last-Mile Delivery

The final element of the outbound logistics process is last-mile delivery, which consists of route planning and optimisation, vehicle monitoring and tracking, fleet management, and proof of delivery.

Fast last-mile delivery is in demand currently. So, it is one of the high-focus areas for a business to provide ultimate customer satisfaction. Nearly 69% of online shoppers are less likely to revisit a store if their order doesn’t make it within two days of the promised delivery date.

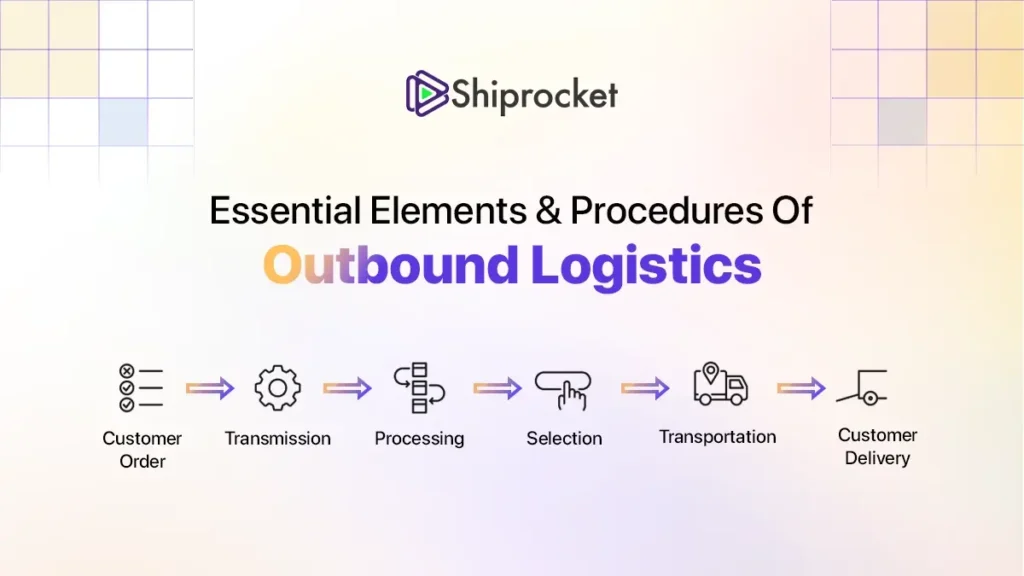

Unveiling the Steps in the Outbound Logistics Process

It takes a series of steps to complete the outbound logistics process effectively:

1. Scanning Orders

First, you must scan the orders to validate them and get rid of any potential errors or redundancies, making sure you send the right order in the appropriate quantity. End customers usually have the option to edit or change their orders by adding, replacing, or removing items before they’re set to go out for delivery.

Incorporating a strong order validation process is a great tool to get timely notifications about any changes in an order, giving you a chance to respond or act accordingly.

2. Restocking

Companies mostly replenish their stock to prepare it for future deliveries or pending orders. They replace products as they receive an order by either transporting available items from a secondary storage facility to a primary location or making new products to move fresh stock into the warehouse.

Adequate quantities of stock enhance your preparedness for upcoming customer orders and reduce the possibility of production or delivery delays, making your outbound logistics more efficient.

3. Final Checks

Between the production to final shipping stage, businesses mostly inspect the products to ensure they meet all quality standards and are intact and well-functioning. As the team sees it up to the mark, they label and pack the products before onboarding them for shipment.

If your inspection is thorough enough, it can reduce returns or repeat shipments and bring greater customer satisfaction.

4. Shipping

Having your shipment delivered to its intended destination is the last stage of this process. Your team can record the process, taking any necessary notes for documentation along the way. You can use this documentation later for reference to respond to customer queries or feedback if required.

An advanced order-tracking system can help you document every step of the delivery process. This constant monitoring eliminates the chances of delays and helps promptly resolve any shipping problems for a successful delivery.

Strategies for Optimising Outbound Logistics

Using cutting-edge technology and the latest techniques is the perfect way to streamline your outbound logistics. Here are two effective strategies:

Route Planning and Efficiency

Researching and figuring out the best delivery routes for your drivers is fairly important to move your inventory to your distribution centers and end customers speedily and efficiently. But this is more than just looking for a shortcut, it rather means you need to minimise external factors.

However, planning routes manually can take up time. You can use route optimisation software that provides automated data imports, real-time updates, and algorithmic sequencing to reduce your planning time dramatically.

Delivery Coordination

If you want to land the right products in the right place when needed, you need proper dispatch management to coordinate the delivery well. With each customer order, it is important to match your customers’ requests and get your delivery drivers ready to transport the goods.

You must reduce your labour costs and service time by assigning the delivery to the right driver at the right hour for timely and successful deliveries.

The Advantages of Optimised Outbound Deliveries

If you manage to optimise your outbound delivery logistics, you will end up having happier and more loyal customers, curtail your overall costs, and enjoy higher profits.

With an optimised route management system, you can:

- Save money: You will spend less on fuel, reduce your driver hours, speed up deliveries, and save decent bucks in the process.

- Speed up deliveries: Quick deliveries are sure to impress your customers, make them stay, and even motivate them to pay more for same-day delivery. It reduces the wait times for customers as products reach the distribution centers and retailers faster.

Besides, there are fewer order cancellations, packages land on the customer’s doorstep in better condition, and they enhance their buying experience with your eCommerce store. According to a report by Bain & Company and Harvard Business School, loyal consumers can be valued at up to 10 times the amount of their first purchase, and increasing customer retention by only 5% can hike profits by 25% to 95%.

Navigating the Distribution Channels in Outbound Logistics

Distribution channels in outbound logistics usually involve a combination of four elements: product manufacturer, wholesaler, retailer, and end consumer. There are mainly three types of channels:

- Full Channel: It Involves all these four elements and is often beneficial when you want to sell a restricted product. Such products may have some legal restrictions, like laws governing the sale of alcohol or certain medicinal drugs.

- One Intermediary: This is a channel where the producer sells the product directly to the retailer, bypassing the wholesaler. It is commonly used by large enterprises selling their products to retail giants.

- Direct-to-Consumer: The D2C route connects manufacturers directly with end consumers, eliminating wholesalers and retailers. Big companies like Apple, with flagship stores and eCommerce platforms, use this channel mostly.

Factors like cost, speed, quality control, logistics complexity, and customer satisfaction can determine which channel would be the best for your business.

Impact of Outbound Logistics on Customer Experience

Optimised outbound logistics can influence how your customer feels about their purchasing experience in many ways:

Your attention to detail in order entry, like entering accurate addresses, prevents delays and negative reviews, preserving your company’s reputation. So, make sure you fill those entry fields correctly, deliver the packages in good condition, and maintain transparency with your customers.

Collecting quality data during the entire outbound logistics process can help you streamline the operations. Enable data sharing and collaboration across teams in your organisation to enhance efficiency and visibility.

You can easily manage your customers’ expectations and boost confidence with an outbound logistics system that provides real-time updates, even if delays are on the charts.

You get more visibility by using technology to plan and track your supply chain activities, like carrier locations. With this advanced visibility and predictive analytics, you can manage your warehouse and transportation much better.

Outbound vs. Inbound Logistics: The Contrasting Features

The process is similar for both, where you buy raw materials from suppliers, manufacture your products, and sell the finished products. However, there are considerable differences in the operations relating to these two types of logistics.

Inbound logistics is where you receive the goods and materials in the first place. For example, if you’re a producer, inbound logistics is how you receive the raw materials to manufacture your finished products. It focuses mainly on supply and your relationship with the suppliers, not involving the end customer.

The outbound logistics network operates in an entirely different way, working with partners separate from the ones in your inbound logistics network. In inbound transit, raw materials suppliers may ship their goods directly to your location, while in outbound transit, your finished products may move to a distribution warehouse that stocks your goods. A retailer later ships these items to other locations to replenish inventories as needed.

Most businesses require taking outbound and inbound logistics into account for better performance.

Conclusion

The outbound logistics industry is much beyond the traditional methods and is inclined towards a more modern approach to alleviate the increased complexities and keep up with the rising demand for faster deliveries.

Strategies like optimal route planning and real-time tracking prevent delays, while automated systems reduce unnecessary stops and streamline paperwork processes. Customised logistics management systems equipped with predictive intelligence optimise decision-making and improve customer satisfaction.

You can upgrade your eCommerce journey – handle production demands better, cut costs, and mitigate risks by updating outbound logistics systems.